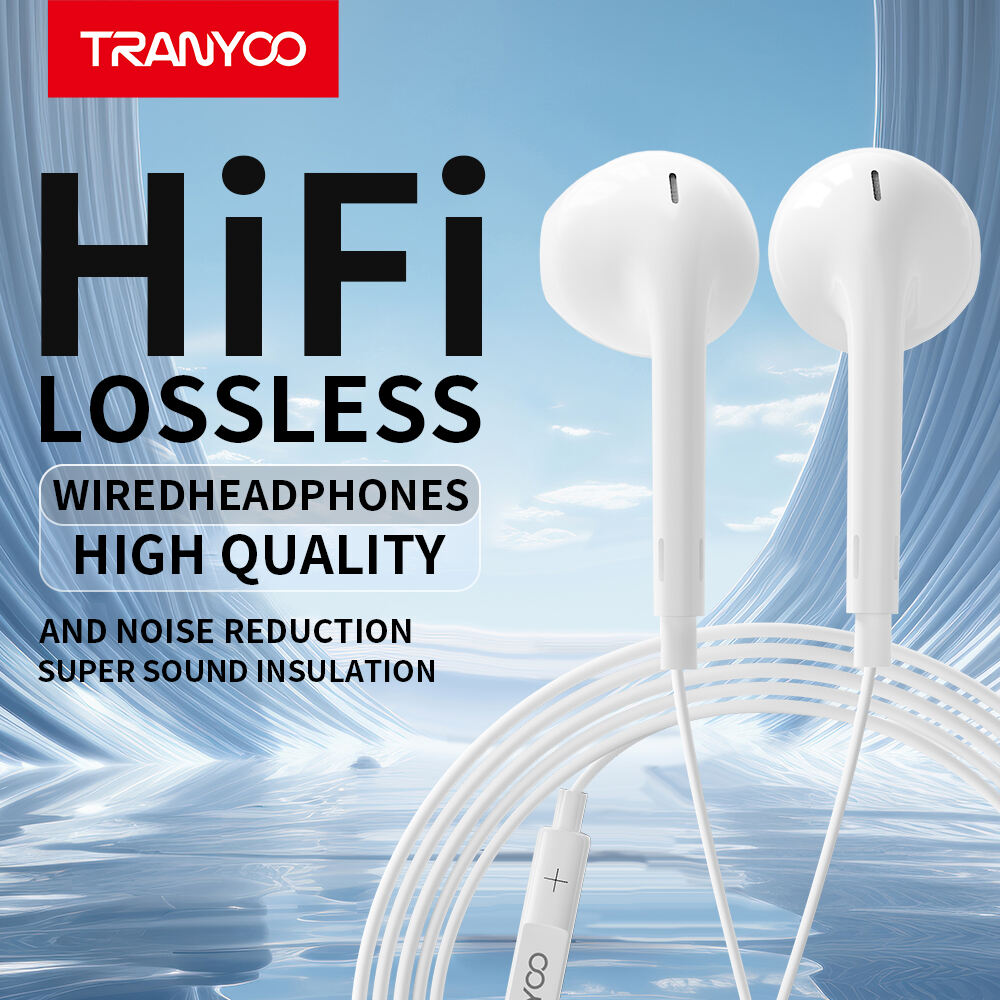

earphones factory

The earphones factory stands as a cutting-edge manufacturing facility dedicated to producing high-quality audio devices with precision and innovation. This state-of-the-art facility encompasses multiple production lines equipped with advanced automation systems and quality control mechanisms. The factory utilizes sophisticated testing equipment to ensure each product meets stringent audio performance standards, including frequency response, sound isolation, and durability testing. The facility features specialized clean rooms for delicate component assembly, automated soldering stations for consistent connections, and advanced acoustic chambers for sound testing. With a production capacity of over 100,000 units per month, the factory implements lean manufacturing principles to optimize efficiency while maintaining product excellence. The facility also houses an R&D center where engineers develop new technologies and improve existing designs, focusing on areas such as driver technology, noise cancellation, and wireless connectivity. Environmental considerations are integrated into the manufacturing process, with energy-efficient machinery and waste reduction programs in place. The factory maintains ISO 9001 certification and employs over 500 skilled workers who undergo regular training to stay current with the latest manufacturing techniques and quality control protocols.