handheld mini fan plants

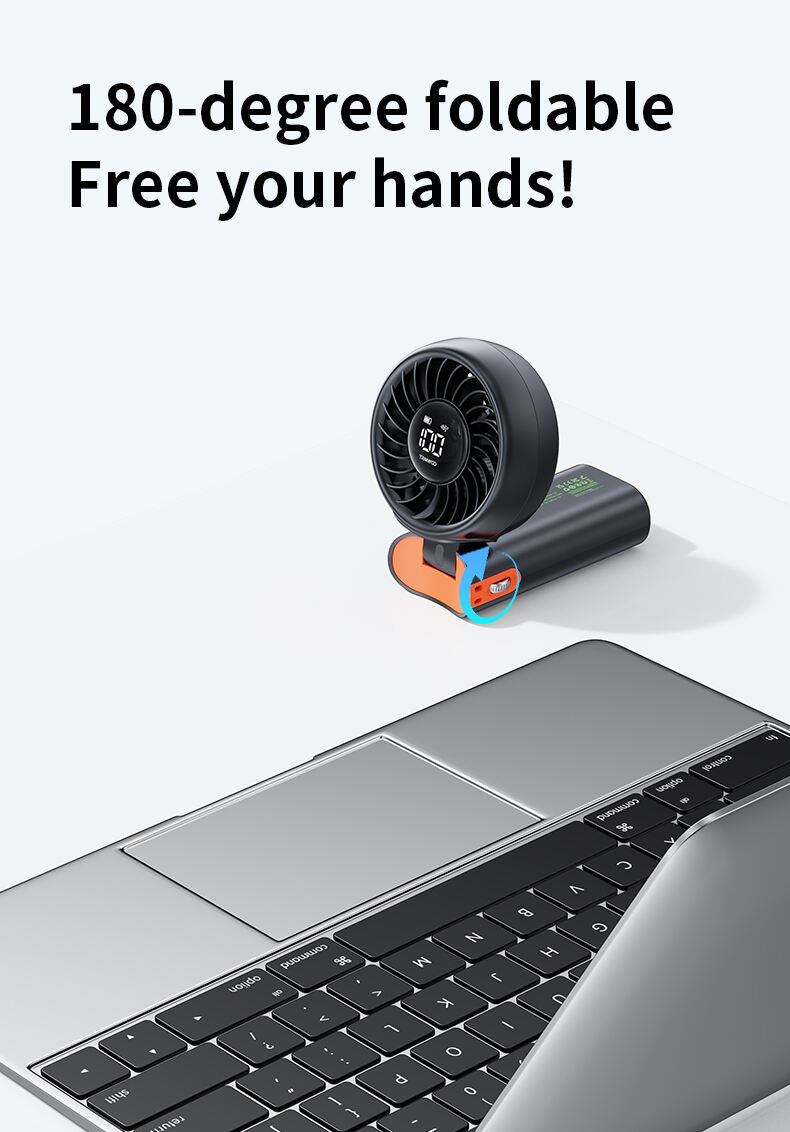

Handheld mini fan plants represent an innovative advancement in personal cooling technology, combining portability with efficient air circulation capabilities. These compact manufacturing facilities are specifically designed to produce portable cooling devices that meet the growing demand for personal comfort solutions. The plants incorporate state-of-the-art assembly lines equipped with precision automation systems, quality control stations, and advanced testing facilities. These manufacturing units typically feature multiple production lines capable of simultaneously producing various models of handheld fans, from basic single-speed units to sophisticated rechargeable devices with multiple speed settings and additional features like LED displays and misting functions. The facilities utilize modern injection molding machines for plastic components, automated circuit board assembly stations, and specialized testing equipment to ensure product reliability and safety standards. Quality control measures are implemented at every stage of production, from raw material inspection to final product testing, ensuring consistency in performance and durability. These plants often incorporate energy-efficient manufacturing processes and sustainable practices, including waste reduction systems and environmentally friendly material handling procedures.