fast charging cable factory

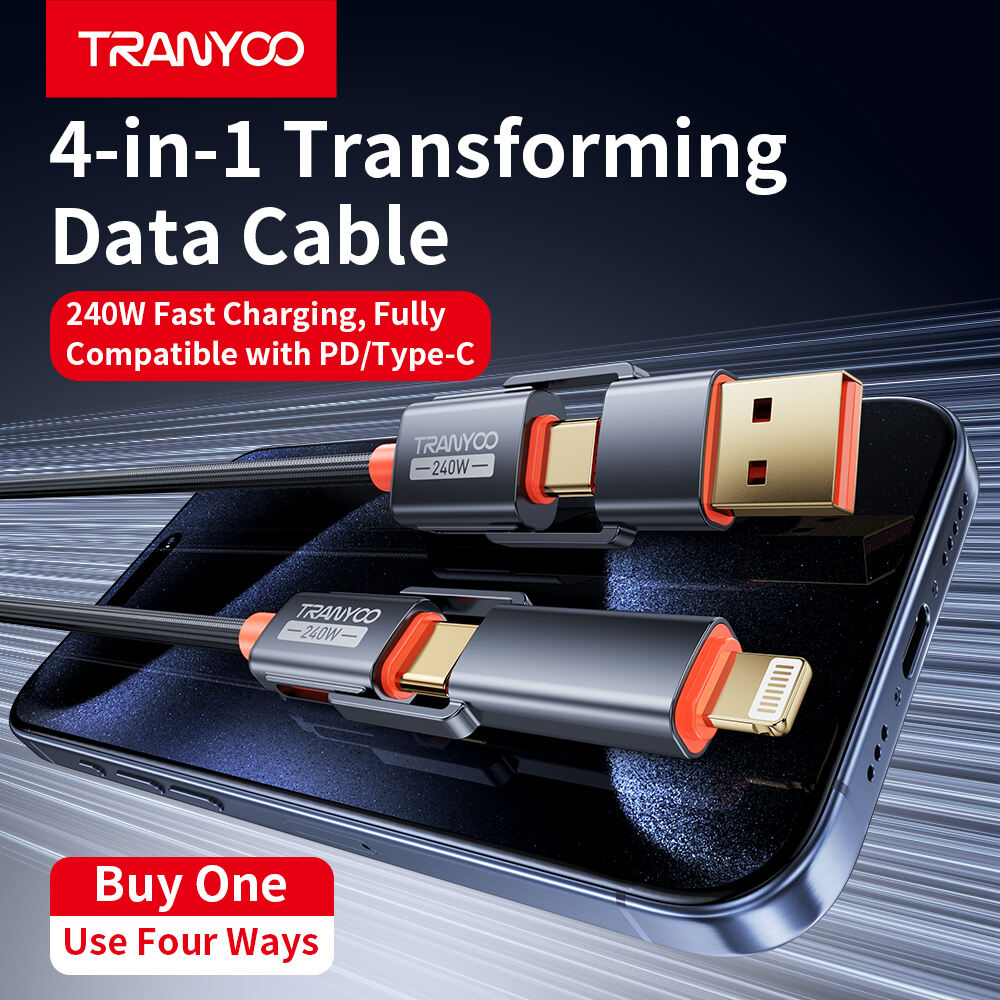

A fast charging cable factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality, efficient charging solutions for modern electronic devices. These facilities integrate advanced automation systems, quality control mechanisms, and innovative production techniques to create cables that support rapid power delivery. The factory employs cutting-edge testing equipment to ensure each cable meets international safety standards and performance specifications. Production lines are equipped with precision machinery for wire drawing, insulation extrusion, braiding, and connector assembly. The facility's capabilities extend to manufacturing various cable types, including USB-C, Lightning, and other proprietary formats, with support for multiple fast-charging protocols such as Power Delivery, Quick Charge, and VOOC. Quality assurance laboratories within the factory conduct rigorous testing for durability, power efficiency, and safety compliance. The facility also maintains strict environmental controls to prevent contamination and ensure consistent product quality. With integrated research and development departments, these factories continuously innovate to improve charging speeds, cable durability, and compatibility with emerging device specifications. The production process incorporates advanced materials science, utilizing high-conductivity metals and specialized insulation compounds to maximize charging efficiency while maintaining product safety.